The process

Find out how Langley Distillery’s high quality award-winning distilled London Dry Gin is crafted.

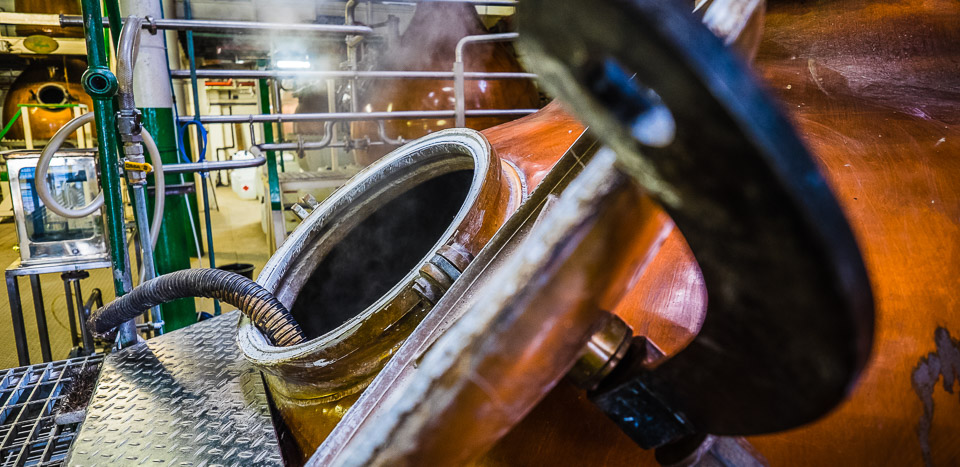

The botanicals are carefully weighed out and added to the still, along with a charge of ethanol and water solution. The still lid is then shut and the steam jacket switched on to allow the gentle warming of the still. This warming process allows the botanicals to begin releasing their oils for distillation; this process of maceration continues over night.